Pressure Vessel Components

At CESSCO Fabrication & Engineering Ltd., we have the experience and resources to fabricate quality pressure vessel components and parts for companies throughout Alberta, British Columbia, Saskatchewan, Manitoba, the Yukon, Northwest Territories, and beyond as well as in the United States.

At CESSCO Fabrication & Engineering Ltd., we have the experience and resources to fabricate quality pressure vessel components and parts for companies throughout Alberta, British Columbia, Saskatchewan, Manitoba, the Yukon, Northwest Territories, and beyond as well as in the United States.

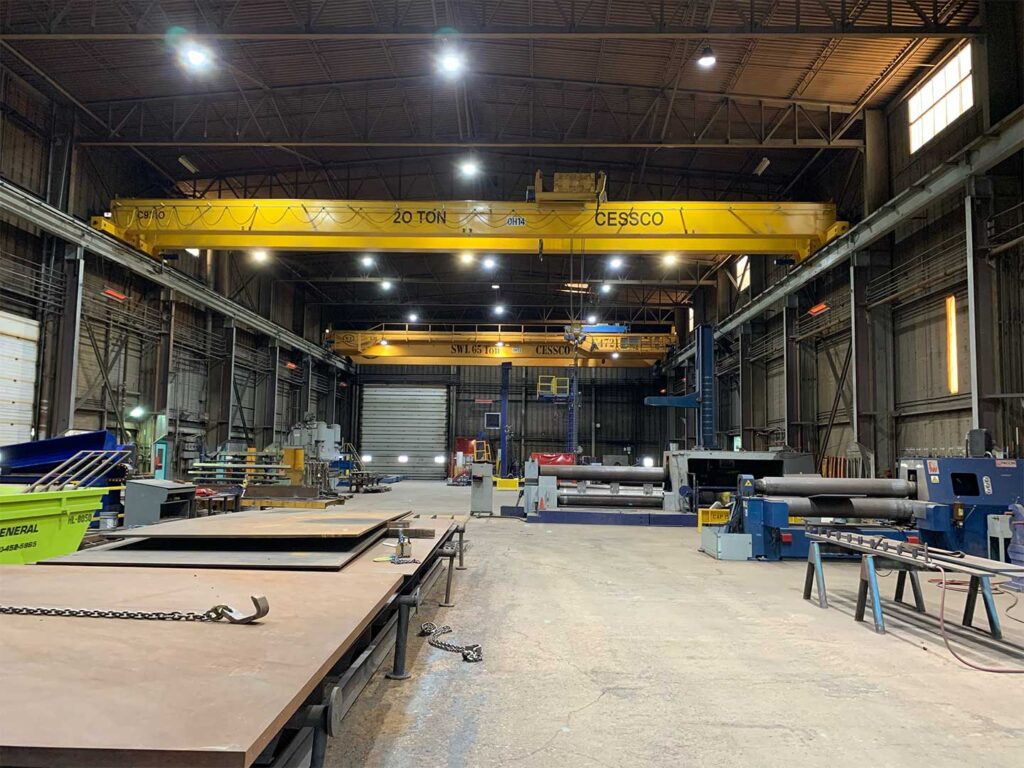

We have a solid reputation as a custom metal fabricator in Western Canada with a diverse line of equipment capable of meeting unique requirements for various industries, and our spacious facility allows us to fabricate various components simultaneously.

Along with providing innovative solutions for our pressure vessel customers, some of our capabilities include plate rolling, plate bending, cone forming, plasma cutting, and fabrication of heads, nozzles, repads, pipe spools, base plates, saddle parts, lifting lugs, tail lugs, and other attachments.

We can offer a fast turnaround time from the day you first approach us to the moment the components are released to you.

Because quality control is paramount throughout the entire manufacturing process, our certified team members conduct regular inspections and use non-destructive examinations (NDE) as part of our project requirements and due diligence to ensure the integrity of each component.

Contact us: componentsales@cessco.ca

Shell & Plate Rolling for Pressure Vessel Construction

With our advanced plate rolling procedures, cutting-edge equipment, and experienced technicians, we fabricate various high-calibre pressure vessel components with precision.

Plate rolling is a fundamental process in our fabrication projects, as it enables us to shape flat metal plates into cylindrical and conical forms that become the body of pressure vessels. We have the expertise and equipment to work with thicknesses up to eight inches, and we have rolling capabilities to roll for diameters of up to 36 feet. Additionally, our shop services include cutting and beveling various attachments, and plate rolling for repads, saddles, rings, or other needs.

Manufacturing of Pressure Vessel Heads

Throughout our history in the custom heavy fabrication industry, we have developed the proficiency to manufacture various pressure vessel heads.

We understand the importance of ASME head design, as it is a crucial component of the overall structural integrity and efficiency of a pressure vessel, and we have the expertise to comply with the unique requirements of each project. Our head supply experience includes designing hemispherical and ellipsoidal heads for clients in any industry, which we can provide to you untrimmed, trimmed, or beveled (single or double), depending on your needs.

Custom Pressure Vessel Component Fabrication

When you design and build pressure vessels on the scale we specialize in, the component parts need to be custom-built to comply with unique design and process requirements.

It’s your component parts that are most likely to fail first. Having them and your vessel as whole regularly inspected and maintained is the best way to protect your employees and worksites from extremely dangerous and destructive equipment failures. We fabricate replacement and new pressure vessel and tank components, including nozzles, piping, cones, repads, baffles, trays, and more as well as perform custom profile cutting.

Pressure Vessel Component Projects

See our past work in pressure vessel component design and fabrication for clients across Canada and the United States.

Contact CESSCO for Pressure Vessel Component Fabrication Services

Looking for someone exceptional under pressure? Contact us to inquire about our pressure vessel and pressure vessel component fabrication and engineering services.